Moreover, a report by Grand View Research emphasizes that the demand for wafer valves is driven by the need for more sustainable and energy-efficient systems. With the increasing regulatory focus on environmental sustainability and energy conservation, wafer valves stand out due to their superior sealing capabilities and reduced risk of leakage. As we delve into the role of wafer valves in modern fluid control systems, it is essential to understand their operational advantages, design specifications, and application scenarios that make them an indispensable choice in today's industrial settings. This comprehensive guide aims to illuminate the pivotal role wafer valves play in enhancing system performance and reliability.

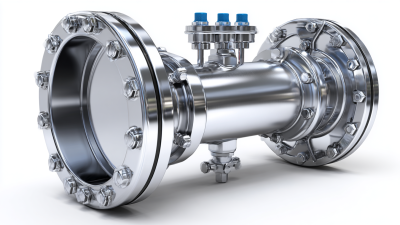

Wafer valves have emerged as an essential component in modern fluid control systems, offering a unique set of features and benefits that enhance performance and reliability. One of the key advantages of wafer valves is their compact design, which allows for easy installation in tight spaces without compromising flow efficiency. This space-saving feature not only helps in reducing the overall footprint of the fluid control system but also translates to cost savings in installation and maintenance.

Another significant benefit of wafer valves is their ability to handle a wide range of pressures and temperatures, making them versatile for various applications. Their robust construction ensures durability, providing long-lasting performance even in challenging environments. Furthermore, wafer valves offer excellent sealing capabilities, which minimize leakage and improve system integrity.

Tip: When selecting a wafer valve for your system, consider the specific pressure and temperature requirements of your application to ensure optimal performance.

Additionally, wafer valves can simplify maintenance procedures due to their straightforward design, allowing for quick access and serviceability. Users can easily replace or service the valves without requiring extensive downtime, thus minimizing operational disruptions.

Tip: Regular inspections of wafer valves can help in identifying wear and tear early, allowing for proactive maintenance and prolonging the lifespan of your fluid control system.

Wafer valves, often overshadowed by their traditional counterparts like globe or gate valves, have carved a unique niche in modern fluid control systems. Their compact design and lightweight structure make them especially suitable for applications where space is limited. According to a recent report by Global Market Insights, the wafer valve market is expected to grow at a CAGR of 5.1% over the next decade, driven by the rising demand for efficient fluid control solutions across various industries, including oil and gas, water treatment, and chemical processing.

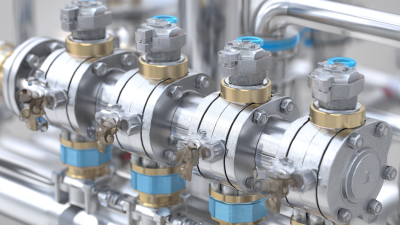

When comparing wafer valves to other types, such as ball and butterfly valves, they exhibit several advantages. Wafer valves typically offer lower operational torque and, as a result, can be more energy-efficient. A survey conducted by the Valve Manufacturers Association highlights that operators prefer wafer valves for specific applications due to their ability to maintain a high flow rate with minimal turbulence. Additionally, their design allows for quicker installation and maintenance, reducing downtime, a critical factor in industrial operations where time and efficiency are paramount. With these benefits in mind, it is clear that wafer valves are not just an alternative but a preferred choice for many fluid control applications.

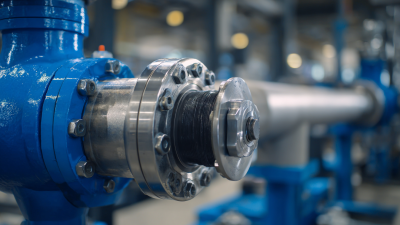

When it comes to wafer valves, proper installation and maintenance are crucial for optimal performance in modern fluid control systems. According to a report by the Valve Manufacturers Association, improperly installed valves can lead to efficiency losses of up to 30%, resulting in increased operational costs. Ensuring that wafer valves are installed according to manufacturer specifications helps mitigate such risks. Pay attention to alignment and the application of appropriate torque during installation to avoid damage and ensure a tight seal.

Maintenance best practices further enhance the longevity and reliability of wafer valves. Regular inspections should be conducted to check for signs of wear and tear, particularly in high-pressure environments. It's advisable to clean the valve seats and inspect sealing materials routinely to prevent leakage and ensure smooth operation. A study from the International Journal of Fluid Flow highlights that effective maintenance can increase a valve's lifespan by 50%, showcasing the importance of a proactive approach.

Tips: Always keep a detailed log of maintenance activities to track performance over time. When replacing any components, opt for OEM parts to maintain compatibility and reliability. Lastly, consider investing in training for your maintenance team to ensure they are equipped with the latest best practices in fluid control systems.

Wafer valves have increasingly become vital components in modern fluid control systems, primarily due to their compact design and efficient operation. Recent advancements in innovative technologies are significantly enhancing the performance of these valves. One notable improvement is the integration of smart sensors that enable real-time monitoring of fluid dynamics. These sensors can detect changes in temperature, pressure, and flow rate, allowing for immediate adjustments to maintain optimal performance. This innovation not only increases reliability but also extends the lifespan of the valve, ultimately leading to cost savings for operators.

Tips for maximizing the effectiveness of wafer valves include regular maintenance checks to ensure that the seals and seating surfaces are in good condition. Applying a suitable lubricant can help in minimizing wear and tear, leading to smoother operation. Additionally, consider the installation environment; ensuring that the valves are placed in a suitable position away from extreme temperatures can enhance their performance and durability. Embracing the latest technologies and best practices will ensure that wafer valves continue to serve crucial roles in fluid control systems efficiently.

The future of wafer valve design is poised for significant advancements, driven by the increasing demand for efficiency and sustainability in fluid control systems. Engineers are increasingly focusing on materials that can withstand harsher environments while maintaining reliability. For example, the use of lightweight and corrosion-resistant composites will not only extend the lifespan of wafer valves but also reduce energy consumption during operation. Innovations in automation and smart technologies are set to revolutionize how these systems operate, allowing real-time monitoring and adaptive control.

Tip: When selecting wafer valves for your system, consider the compatibility of materials with the fluid you are working with to prevent wear and ensure optimal performance.

Additionally, the trend towards modular design is gaining traction, allowing for easier integration and maintenance of wafer valves within existing systems. This modular approach enhances flexibility, enabling engineers to customize fluid control solutions tailored to specific applications. With the rise of Industry 4.0, predictive maintenance through IoT-enabled wafer valves will also become commonplace, further optimizing performance and minimizing downtime.

Tip: Investing in IoT technology for your fluid control systems can lead to significant savings in maintenance costs while improving system efficiency.

This chart illustrates the projected growth in popularity among different types of wafer valves over the next five years, as well as the anticipated advancements in fluid control solutions. The data reflects industry trends and emerging technologies in fluid control systems.

© Shipham Valves 2025. All Rights Reserved.

Website By PS Website Design Ltd

Request a Quote/Further Information

Download

We use cookies on this website, by continuing to browse the site you are agreeing to our use of cookies. Find out more.