The triple offset butterfly valve has emerged as a vital component in various industrial applications, thanks to its unique design and operational advantages. According to a recent report by MarketsandMarkets, the global market for butterfly valves is projected to reach USD 8.2 billion by 2025, with a significant focus on tailored solutions for energy, oil and gas, water treatment, and chemical industries. The triple offset butterfly valve distinguishes itself through its innovative triple offset design, which not only reduces wear and tear but also enhances sealing capabilities, enabling it to handle high-pressure and high-temperature applications effectively. As industries continue to prioritize efficiency and reliability, understanding the intricacies of triple offset butterfly valves becomes essential for engineers and decision-makers aiming to optimize systems and reduce operational costs. With this ultimate guide, we delve into the critical aspects of their functionality, advantages, and best practices in implementation, ensuring that professionals are well-equipped to leverage this technology in their operations.

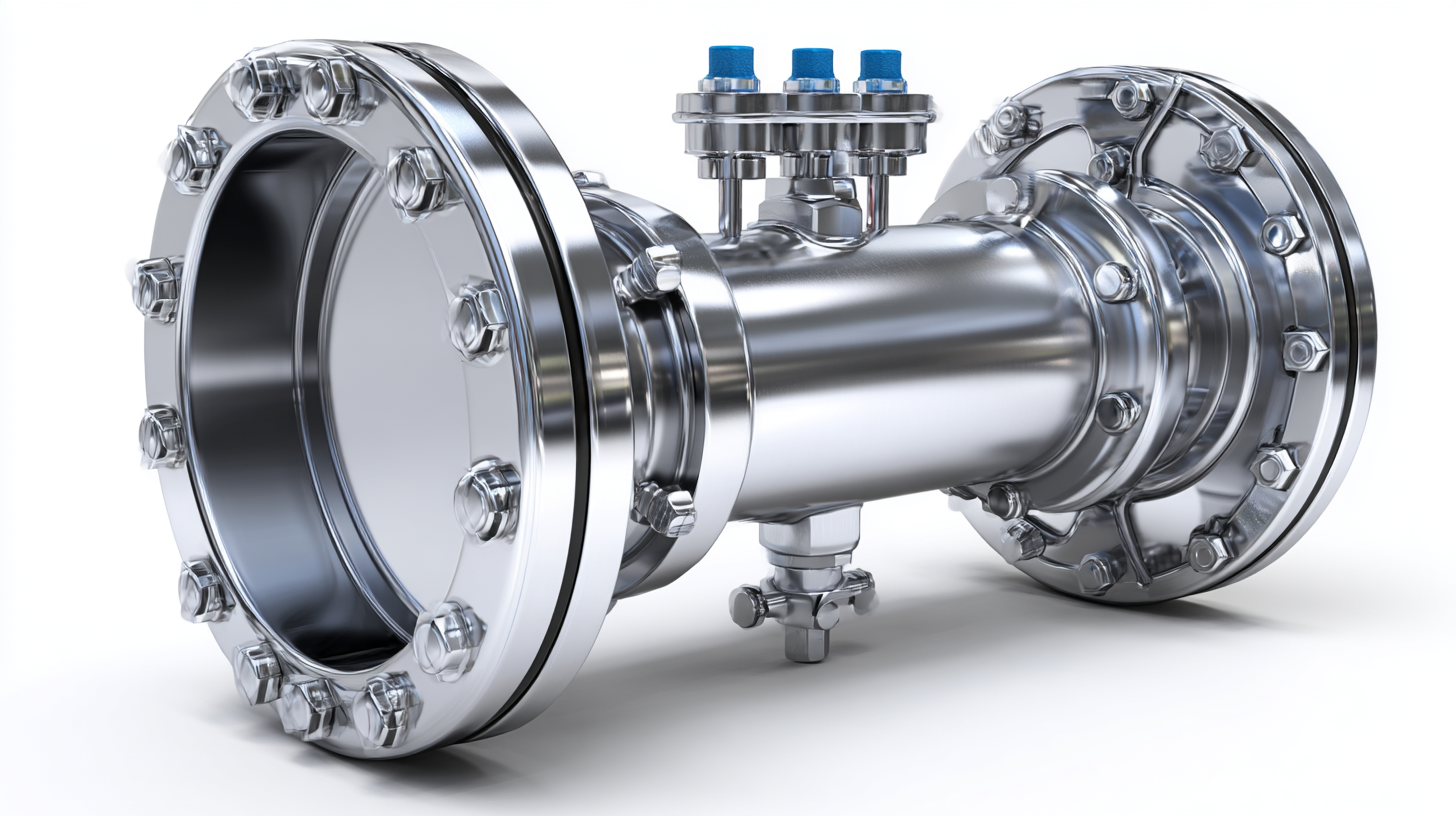

Triple offset butterfly valves are gaining recognition in industrial applications due to their unique design and key features that enhance performance and reliability. One of the most significant characteristics is the triple offset geometry, which provides a tight seal that prevents leakage even under high-pressure conditions. This design minimizes friction during valve operation, leading to extended service life and reduced maintenance requirements. The valve's ability to close with a quarter turn also allows for quick operation, making it an ideal choice for processes that require immediate flow control.

Another essential feature of triple offset butterfly valves is their robust construction, which allows them to withstand harsh operating environments. They are typically made from high-quality materials such as stainless steel or carbon steel, ensuring durability and resistance to corrosion and wear. This durability makes them suitable for a variety of industrial settings, including oil and gas, water treatment, and chemical processing. Additionally, their lightweight design facilitates easier installation and handling, making them a preferred option for engineers and operators looking to optimize performance while reducing operational costs.

Triple offset butterfly valves offer several distinct advantages that make them a superior choice in various industrial applications. Unlike traditional butterfly valves, the triple offset design significantly reduces friction between the valve seat and the disc. This unique configuration ensures a tight seal and minimizes wear over time, allowing for longer operational life and reduced maintenance costs. As these valves operate with less effort, they can also be automated more effectively for precise flow control.

Additionally, the triple offset design provides excellent performance across a wide range of temperatures and pressures. These valves are capable of handling extreme conditions while maintaining integrity, which is crucial in industries such as oil and gas, water treatment, and chemical processing. Their streamlined structure results in lower pressure drops compared to other valve types, enhancing efficiency.

Furthermore, a triple offset butterfly valve's compact design makes it easier to install in systems with limited space, providing flexibility in pipeline configurations without compromising performance.

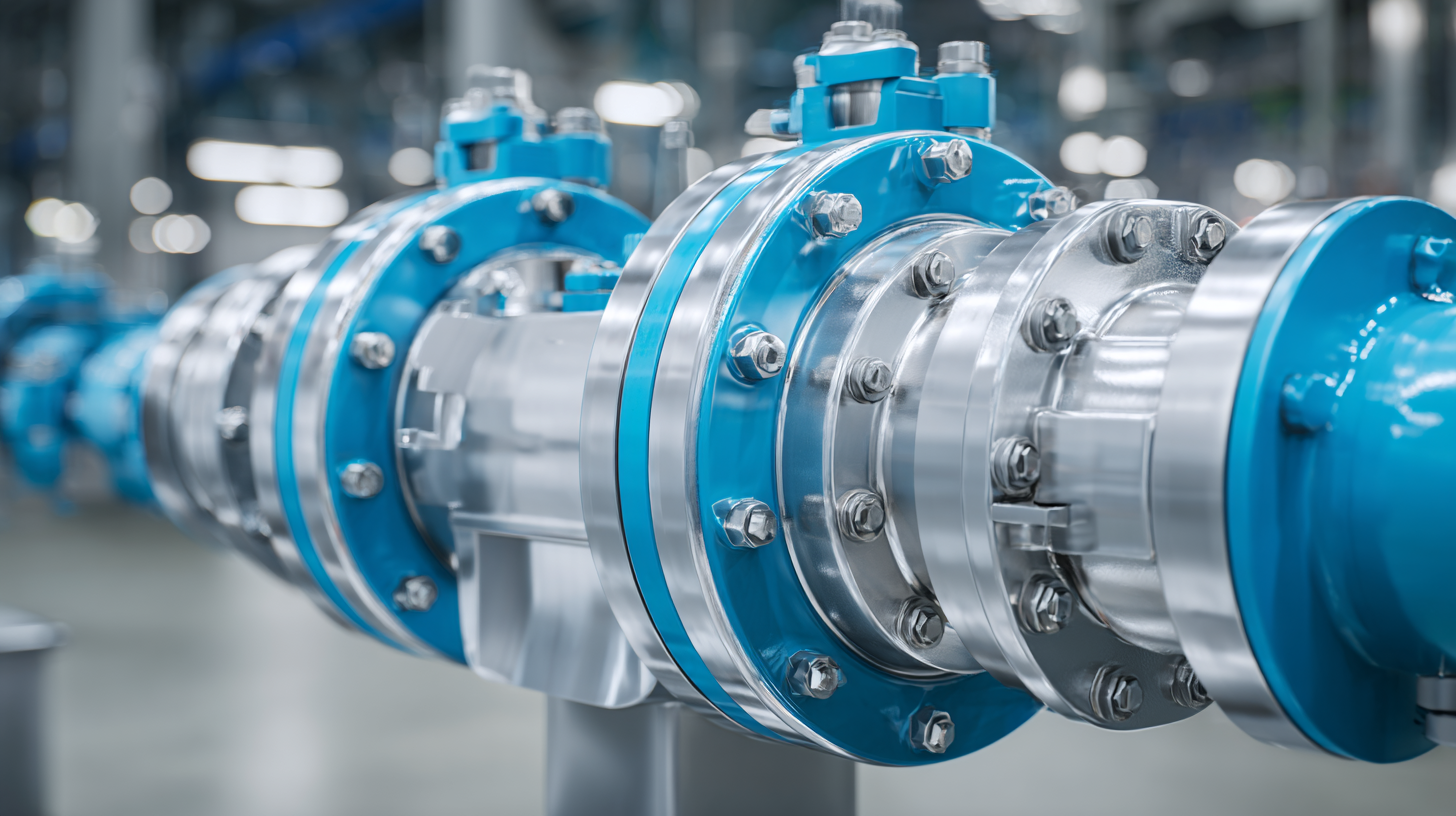

Triple offset butterfly valves have become essential components across various industries due to their unique design, which ensures zero leakage and efficient flow control. With the rising demand for reliable and durable valve solutions, the market for these valves is poised for substantial growth. In particular, sectors such as oil and gas are increasingly adopting triple offset designs for their ability to withstand high pressure and corrosive environments, making them ideal for critical applications.

Recent developments in the butterfly valve market indicate that manufacturers are responding to this demand by expanding their product ranges and introducing advanced models tailored for industrial applications. Innovations such as improved flanged designs are providing comprehensive solutions that contribute to enhanced system efficiency and safety. As industries continue to seek reliable flow control mechanisms, the adoption of triple offset butterfly valves is expected to rise significantly, shaping the future landscape of fluid handling in industrial settings.

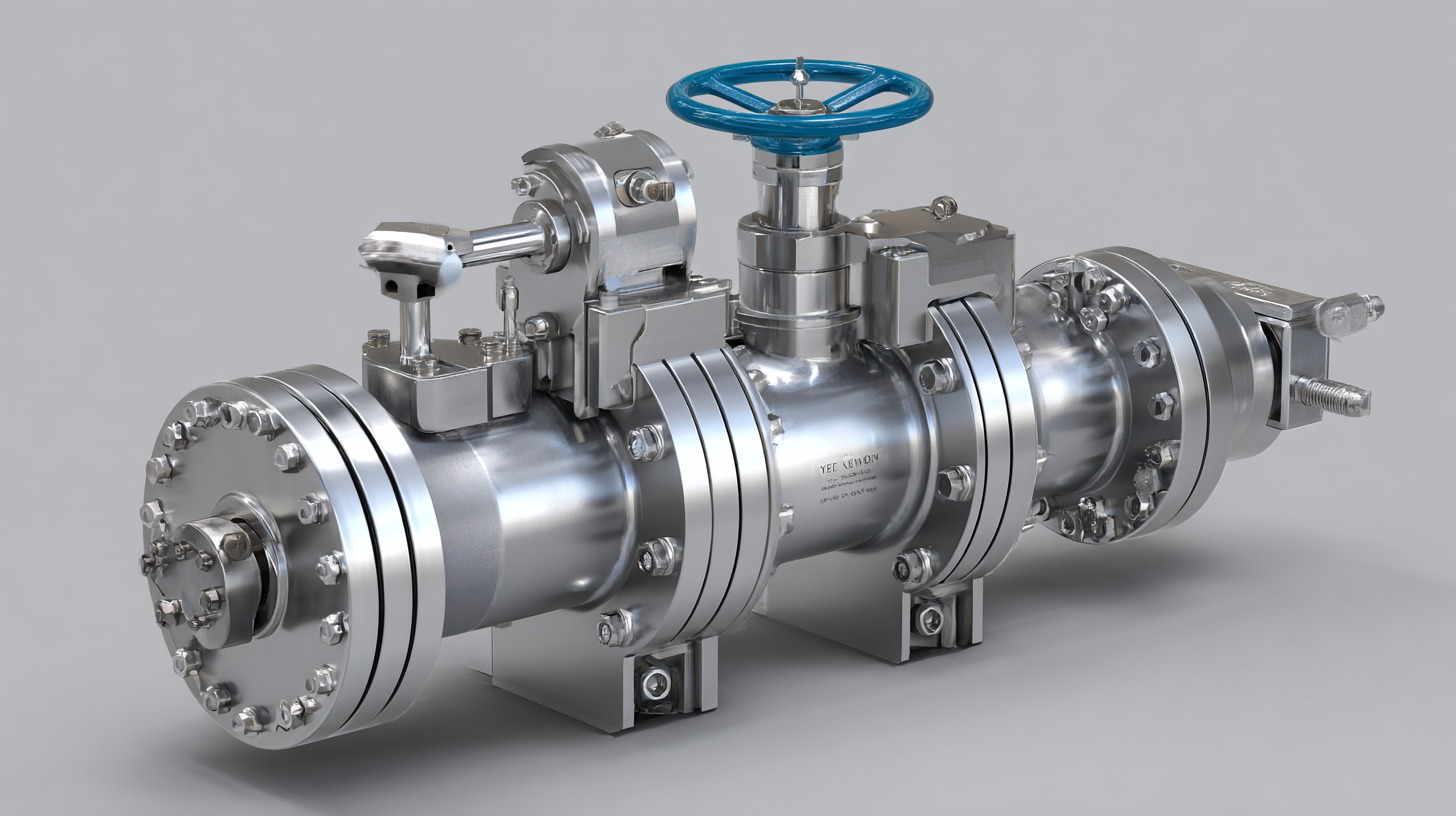

Maintenance of triple offset butterfly valves is crucial for ensuring optimal performance in industrial applications. According to industry reports, regular maintenance can significantly reduce downtime and enhance the reliability of valve operations. It is recommended that facilities implement a scheduled maintenance program that includes routine inspections, lubrication, and replacement of worn components. These protocols not only extend the lifespan of the valves but also minimize unplanned outages, thereby saving costs associated with emergency repairs.

Recent advancements in valve technology, such as the launch of new six-eccentric butterfly valves designed for critical service applications, underscore the importance of adapting maintenance practices to align with evolving industry standards. With innovations driving efficiency, maintaining an up-to-date understanding of best practices is essential. For instance, monitoring valve performance data can identify potential issues before they escalate, thereby enhancing operational safety and efficiency. Furthermore, as companies undergo digital transformation, leveraging data analytics for predictive maintenance can lead to more proactive management of valve health, ultimately reducing the total cost of ownership.

When selecting the right triple offset butterfly valve for your specific needs, it is essential to consider a variety of factors that will impact both performance and efficiency. Triple offset butterfly valves are renowned for their ability to handle high-pressure and high-temperature applications, making them a popular choice in industrial settings. However, the variety in design, materials, and sealing options necessitates a careful assessment of your operational requirements.

Firstly, understanding the fluid characteristics is crucial. The valve material must be compatible with the media it will control, whether it be corrosive substances or high particulate flows. Additionally, the valve size and pressure rating should align with system specifications to ensure optimal flow and prevent leaks. Furthermore, evaluating the actuator type—manual or automated—can influence the valve's overall functionality and ease of operation. By thoroughly understanding these parameters, you can confidently select a triple offset butterfly valve that will effectively meet your operational demands and enhance system reliability.

This chart illustrates the performance characteristics of two different models of triple offset butterfly valves. The parameters evaluated include temperature resistance, pressure rating, flow coefficient, weight, and size. This information can assist users in selecting the appropriate valve based on their specific industrial needs.

© Shipham Valves 2025. All Rights Reserved.

Website By PS Website Design Ltd

Request a Quote/Further Information

Download

We use cookies on this website, by continuing to browse the site you are agreeing to our use of cookies. Find out more.