In modern engineering applications, the integration of efficient control systems is paramount to enhancing operational reliability and performance. The "3 valve" system has emerged as a critical configuration in various industries, including oil and gas, pharmaceuticals, and water management. According to a recent report by the American Society of Mechanical Engineers (ASME), approximately 35% of industrial processes have adopted advanced valve systems to optimize flow control and reduce energy consumption. This is complemented by a market analysis from MarketsandMarkets, which projects that the global valve market will reach $80 billion by 2025, with 3 valve systems playing a pivotal role in this growth. By enabling precise modulation of fluid movement and improving safety through redundancy, the 3 valve design not only enhances process efficiency but also supports sustainability goals by minimizing waste. As industries continue to evolve, understanding the role and benefits of 3 valve systems becomes increasingly essential.

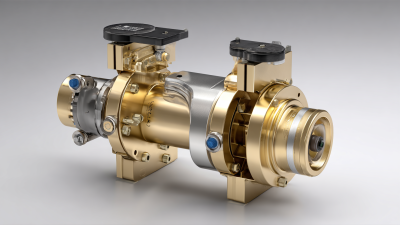

The evolution of 3 valve systems in engineering practices has been marked by significant advancements that enhance efficiency and reliability in various applications. Originally, these systems were designed to control fluid flow in a straightforward manner. Over the years, innovations in materials and design have facilitated the development of more robust valve mechanisms capable of withstanding higher pressures and temperatures. This transformation has made 3 valve systems indispensable in industries such as petrochemical, water treatment, and HVAC, where precise control over fluid dynamics is crucial.

As engineering practices have progressed, the integration of automation and smart technologies into 3 valve systems has further elevated their relevance. Today's systems often feature sensors and actuators that allow for real-time monitoring and adjustment, improving operational efficiency and safety. The shift toward sustainability in engineering has also influenced the design of these systems, leading to solutions that reduce waste and energy consumption. The continuous evolution of 3 valve systems mirrors the broader trend within the engineering field toward smarter, more sustainable practices aimed at meeting modern demands.

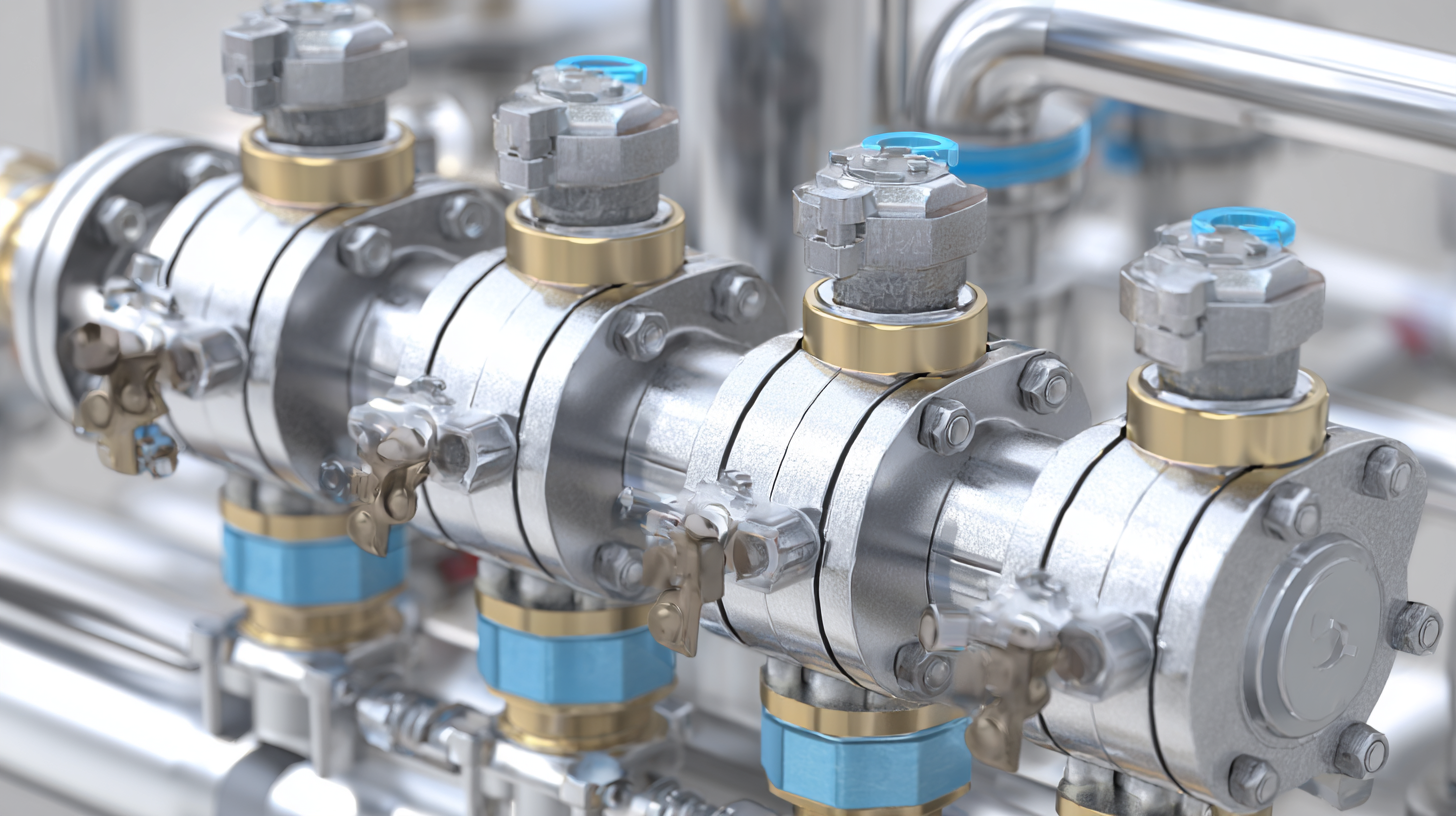

Three valve systems play a crucial role in various modern engineering applications, particularly in industries such as oil and gas, water management, and chemical processing. These systems primarily consist of three main components: the inlet valve, the outlet valve, and a bypass valve. Together, they effectively manage fluid flow, pressure, and temperature, ensuring both safety and efficiency in operations.

According to the Global Market Insights report, the valve market is expected to exceed USD 100 billion by 2026, driven largely by advancements in valve technologies and increased demand for automation across various sectors.

The functionality of these valves is integral to maintaining process integrity and operational flexibility. The inlet valve controls the entry of fluids into the system, while the outlet valve governs discharge. The bypass valve enables flow regulation without the need for complete shutdown, which enhances downtime efficiency and reduces maintenance costs. A study by Frost & Sullivan highlighted that implementing advanced valve control technologies can lead to a 20% increase in operational efficiency. This underscores the importance of understanding these key components not only for optimizing system performance but also for achieving sustainable engineering practices.

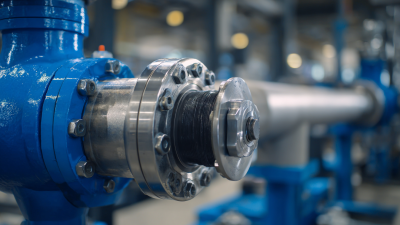

The implementation of 3 valve systems in modern engineering applications brings forth numerous advantages that enhance overall efficiency and reliability. According to a report by the American Society of Mechanical Engineers (ASME), systems employing 3 valves can improve control precision by up to 30%, making them vital in fields such as chemical processing and oil & gas. By providing excellent isolation and drainage capabilities, these systems help in minimizing downtime during maintenance operations, thus prolonging equipment lifespan and reducing operational costs.

Moreover, 3 valve configurations are particularly beneficial in enhancing safety protocols. The National Fire Protection Association (NFPA) indicates that such systems can help prevent hazardous material leaks by ensuring that pressure relief valves operate under optimal conditions. This not only safeguards operators but also protects the environment by reducing the likelihood of spills and contamination.

**Tip:** When designing a 3 valve system, ensure that each valve is easily accessible and clearly labeled to streamline maintenance and operational safety. Regularly testing the system's integrity is also key to preventing potential failures that could disrupt production.

The innovative use of 3 valve systems has gained traction across various industries, primarily due to their efficiency and versatility. In the oil and gas sector, these systems are crucial for isolating sections of pipes, allowing for maintenance without significant downtime. By employing a combination of isolation and bleed valves, operators can safely manage pressure and ensure fluid transfer is seamless, which enhances operational reliability and safety.

In the automotive industry, 3 valve systems are utilized in engine management to optimize performance and fuel efficiency. By controlling the intake and exhaust processes, these systems can significantly improve power output while reducing emissions. Additionally, in HVAC applications, 3 valve setups help regulate heating and cooling systems, enabling better climate control in buildings and vehicles. Their ability to adapt to various operational requirements makes 3 valve systems an integral component in modern engineering solutions.

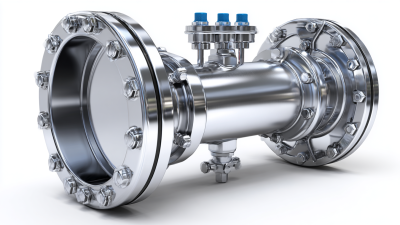

The future trends and developments in three-valve system technologies are increasingly shaping modern engineering applications. The global market for four-way directional valves is projected to experience stable growth, with a market size of approximately 40.043 million USD in 2023, expected to rise to 41.456 million USD by 2024. This growth is particularly evident in the United States, driven by a rising demand for advanced HVAC systems. The integration of smart technologies into these systems signifies a shift toward more efficient and responsive engineering solutions.

Moreover, the automotive industry's move towards increased intelligence is pushing the demand for electronic expansion valves, which play a critical role in climate control and efficiency. The market for electronic expansion valves reached around 4.2 billion USD in 2023, with sales estimated at 114.3 million units. This transformation is indicative of a broader trend in global manufacturing, emphasizing the need for high-end, green, and intelligent technologies. As industries strive for enhanced efficiency, the trend toward smart manufacturing and the seamless integration of components will remain a priority in future developments.

© Shipham Valves 2025. All Rights Reserved.

Website By PS Website Design Ltd

Request a Quote/Further Information

Download

We use cookies on this website, by continuing to browse the site you are agreeing to our use of cookies. Find out more.