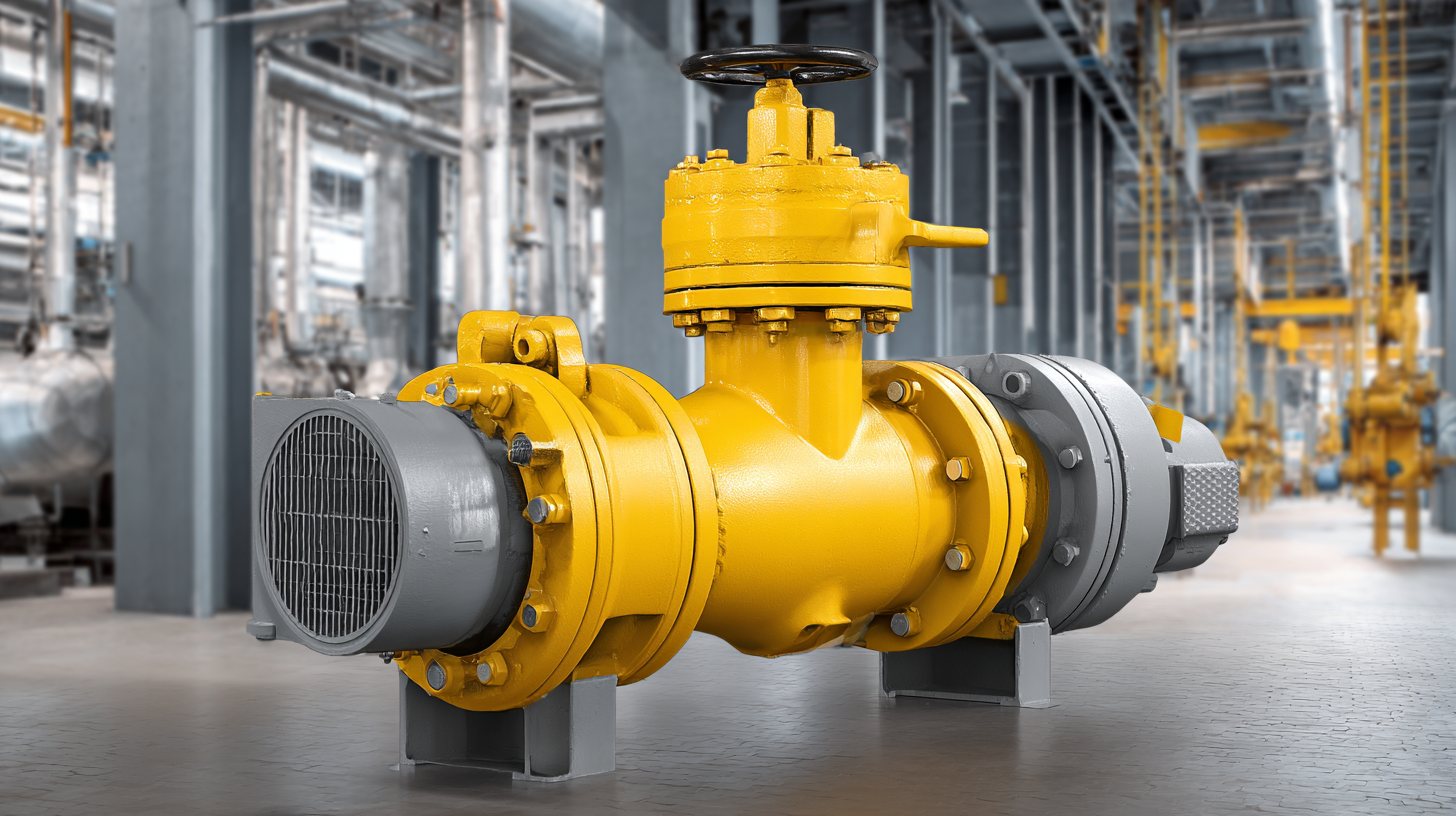

In the realm of fluid control systems, the significance of a reliable swinging mechanism cannot be understated. As we look toward 2025, innovations in swing check valve technologies promise to enhance efficiency and reliability across various applications. According to a recent market analysis by the Flow Control Industry Association, the global swing check valve market is projected to grow by 8.5% annually, driven by advancements in materials and design that cater to demanding industrial environments. As noted by Dr. Emily Carter, a leading expert in fluid dynamics, "The future of swing check valves lies in their ability to respond dynamically to flow changes, thereby minimizing the risk of backflow and ensuring optimal performance."

The increasing focus on sustainability and efficiency in industrial processes underscores the need for innovative solutions in flow control. In sectors ranging from water treatment to oil and gas, the application of high-performance swing check valves is becoming essential. Recent innovations include the integration of smart technologies that allow for real-time monitoring of valve performance, enhancing both safety and maintenance protocols. As highlighted in the 2023 Valve Industry Report, "Smart swing check valves are not only revolutionizing flow management but are also paving the way for more sustainable industrial practices." As we explore the top innovations in swing check valves for 2025, it is crucial to recognize their potential in transforming the efficiency of fluid transport systems worldwide.

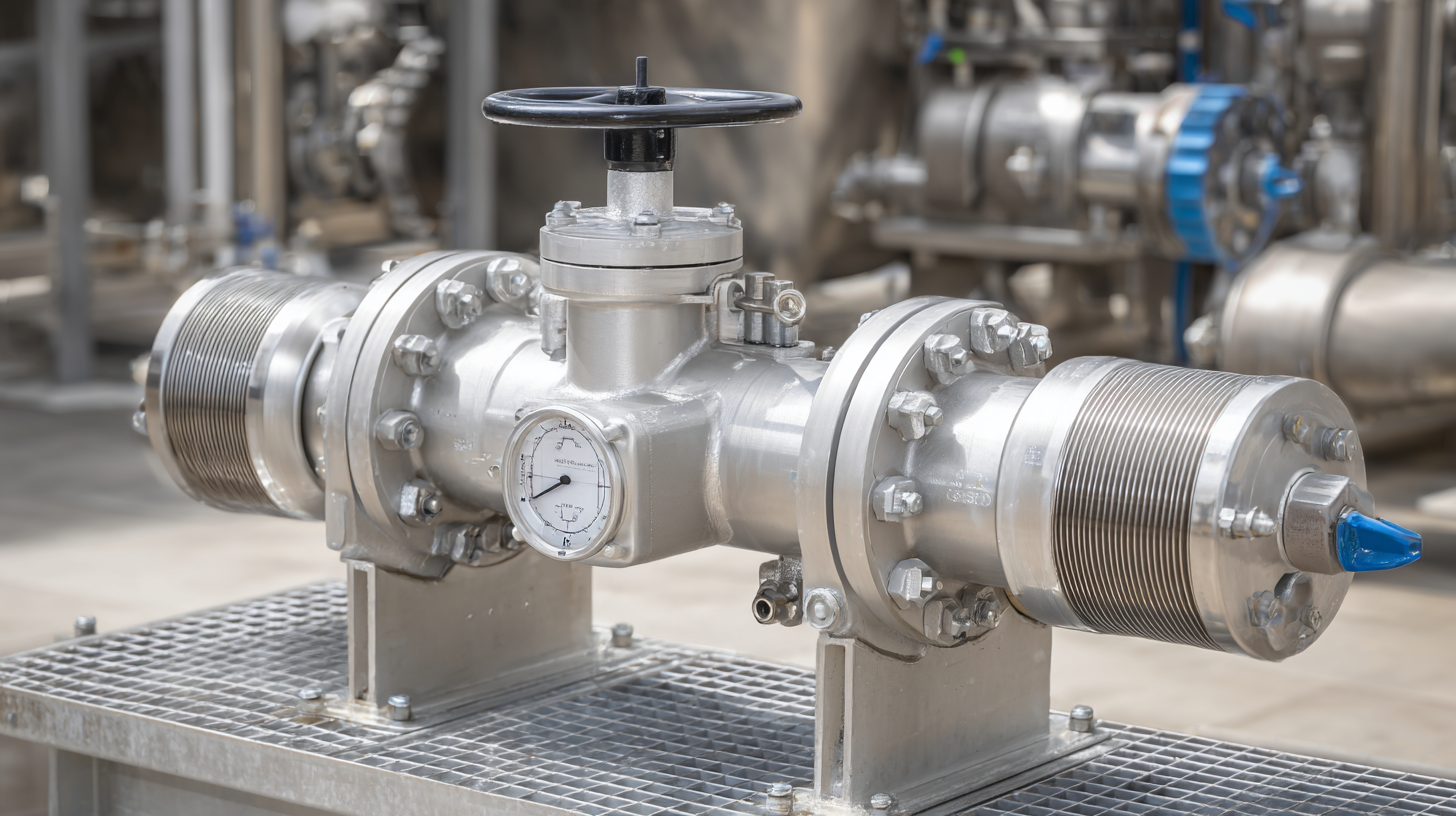

The advancements in swing check valve materials are pivotal for enhancing durability and performance in flow control systems. As the control valve market continues to grow, projected to surge from $7.8 billion in 2024 to $15.5 billion by 2032, innovations in materials are crucial for maintaining efficiency and reliability in diverse applications. New composite materials and biopolymers are being developed to withstand harsh conditions, reducing wear and tear while offering improved resistance to corrosion and fatigue. These enhancements not only prolong the lifespan of valves but also contribute to more sustainable practices in industrial operations.

Furthermore, the integration of bioinspired design principles in swing check valves is revolutionizing flow control mechanisms. By mimicking natural designs found in soft-bodied animals, engineers are creating valves that operate with greater efficiency and adaptability in complex environments. This innovative approach not only optimizes flow but also aligns with the broader trends in the control valve market, which is expected to reach approximately $10.42 billion in revenue by 2025. As manufacturers invest in research and development of advanced materials and designs, the future of swing check valves looks promising, offering enhanced performance in an ever-evolving industry landscape.

| Material | Durability (Years) | Temperature Range (°C) | Flow Efficiency (%) | Weight (kg) |

|---|---|---|---|---|

| Stainless Steel | 15 | -50 to 200 | 95 | 5 |

| Ductile Iron | 20 | -10 to 120 | 90 | 9 |

| PVC | 10 | 0 to 60 | 85 | 3 |

| Bronze | 25 | -30 to 150 | 92 | 7 |

| Carbon Steel | 18 | -40 to 250 | 88 | 11 |

The swing check valve market is projected to witness significant innovations by 2025, driven by advancements in materials and design efficiencies. According to a recent industry report, manufacturers are expected to achieve an average efficiency improvement of 25% in swing check valves, thanks to the introduction of lightweight composite materials and enhanced sealing technologies. These innovations not only reduce installation and maintenance costs but also increase the longevity and reliability of the valves in various applications.

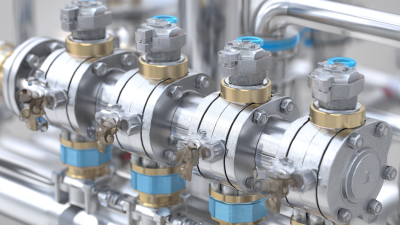

Moreover, the global swing check valve market is expected to grow at a compound annual growth rate (CAGR) of 7% from 2023 to 2025. A key factor contributing to this growth is the rising demand for efficient flow control systems across multiple industries, including oil and gas, water treatment, and energy generation. By 2025, it's estimated that over 60% of swing check valve installations will incorporate smart technology, allowing for real-time monitoring and adjustments that further enhance operational efficiency. This data underscores the critical role that innovation will play in shaping flow control solutions for the future.

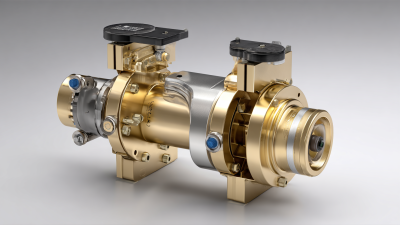

The innovative designs in swing check valves set to emerge in 2025 will significantly enhance flow control across various systems. These advancements are driven by the need for efficiency, reliability, and reduced maintenance costs. Manufacturers are focusing on materials that offer better durability and resistance to corrosion, thus prolonging the lifespan of the valves.

Integration of smart technology into valve designs also allows for real-time monitoring, enabling operators to optimize performance and preemptively address potential issues, ensuring a more streamlined workflow.

Integration of smart technology into valve designs also allows for real-time monitoring, enabling operators to optimize performance and preemptively address potential issues, ensuring a more streamlined workflow.

Additionally, the trend towards modular designs in swing check valves provides flexibility in installation and maintenance. This innovation allows users to tailor configurations based on specific system requirements, improving overall operational efficiency. Enhanced flow characteristics, such as reduced turbulence and increased flow capacity, are being achieved through advanced computational fluid dynamics design processes. These developments not only improve performance but also contribute to energy savings, making modern swing check valves a key component in sustainable engineering practices for 2025 and beyond.

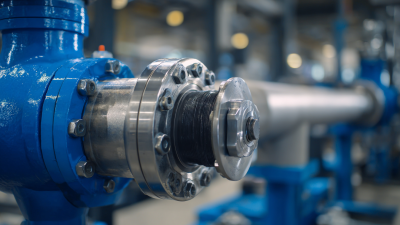

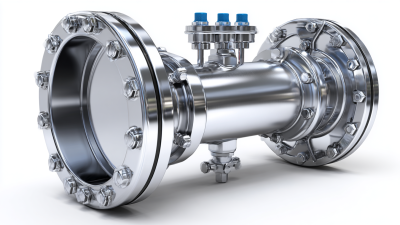

The advent of smart technology is revolutionizing the functionality of swing check valves, which play a critical role in fluid systems. Real-time monitoring capabilities enhance their applications by providing immediate feedback on valve performance and system integrity. These innovative systems enable operators to detect anomalies, allowing for proactive maintenance and minimizing the risk of costly downtime. By integrating sensors and IoT connectivity, users can gain insights into pressure, flow rates, and valve positioning, leading to more efficient flow control.

**Tips:** When incorporating smart technology into your swing check valve systems, consider selecting valves with robust sensor compatibility to ensure seamless integration. Regularly update monitoring software to take advantage of the latest features and security protocols. Additionally, establish a routine for data analysis to identify trends that could indicate potential problems early.

With the push towards automation, the focus on energy efficiency is also heightened. Smart swing check valves can adjust their performance based on real-time data, optimizing operations and reducing energy consumption. This capability not only supports environmental sustainability but also lowers operational costs. Embracing these innovations positions your systems for improved performance and reliability in an increasingly competitive landscape.

As we look towards 2025, the market for swing check valves is poised for significant growth, driven by advancements in technology and increasing demand across various industries.

The adoption rates are expected to rise as organizations prioritize efficient flow control systems that minimize turbulence and maximize longevity.

Key sectors such as water and wastewater management, oil and gas, and HVAC systems are likely to be at the forefront of this trend, implementing innovative solutions to enhance operational reliability.

Moreover, the integration of smart technologies and IoT capabilities into swing check valves is anticipated to revolutionize the way these systems are monitored and maintained.

With real-time data analytics, operators can predict maintenance needs and prevent failures, resulting in reduced downtime and operational costs.

This proactive approach is expected to significantly boost the acceptance of swing check valves, facilitating their adoption in new projects and upgrades of existing infrastructures.

As a result, the landscape of flow control systems is set to transform dramatically by 2025, making swing check valves an essential component in efficient fluid management strategies.

© Shipham Valves 2025. All Rights Reserved.

Website By PS Website Design Ltd

Request a Quote/Further Information

Download

We use cookies on this website, by continuing to browse the site you are agreeing to our use of cookies. Find out more.