In the ever-evolving landscape of gas safety, understanding how to choose the best gas safety valve for your specific needs has never been more critical. As we approach 2025, advancements in technology and safety regulations present a wealth of options. To navigate this complex field, it is essential to rely on expert guidance. Dr. Emily Hart, a leading authority in gas safety engineering, emphasizes, "Selecting the right gas safety valve is not just about compliance; it’s about ensuring the safety of everyone who uses gas in their environment."

Choosing the right gas safety valve can significantly influence the effectiveness of your gas management system. With various types available, each with its own set of features and specifications, decision-makers must take into account factors such as pressure ratings, material compatibility, and application context. Inadequate selection could lead to catastrophic failures, making the understanding of gas safety valves paramount. As Dr. Hart states, "A well-chosen gas safety valve is pivotal in preventing accidents and safeguarding both property and lives."

As we delve deeper into this guide, we will explore essential criteria and industry insights to aid you in making an informed choice. By doing so, you can enhance safety measures and contribute to a more responsible gas usage in your facilities, echoing the sentiment shared by experts like Dr. Hart in prioritizing safety above all.

When selecting a gas safety valve, it's essential to understand the different types available to ensure you choose the right one for your application. The most common types include the automatic shutoff valve, which closes the gas supply under emergency conditions, and the pressure relief valve, designed to release excess pressure to prevent potential hazards. These valves are crucial for maintaining safety in residential, commercial, and industrial settings.

Another important category is the non-return valve, which prevents gas from flowing back into the supply line, thereby reducing the risk of leaks and contamination. There are also solenoid valves that can be operated electronically, providing convenience and remote control capabilities.

Understanding these variations allows users to assess their specific safety requirements and select a valve that meets their operational demands effectively. Choosing the right type plays a key role in enhancing safety and efficiency in gas handling systems.

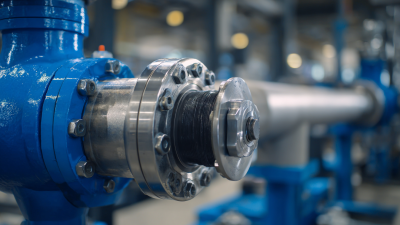

When selecting a gas safety valve, several key features should be at the forefront of your decision-making process. First and foremost, consider the valve's pressure rating. It's essential to choose a valve that can handle the maximum pressure of your system to ensure safe operation. Additionally, look for valves that comply with industry standards and regulations, as this ensures reliability and safety.

Another critical feature is the valve's material. Different materials are suited for various environments and gas types. For example, if you are working in a corrosive environment, opting for a stainless steel valve could enhance longevity. Furthermore, assess the valve's size and connection type to ensure compatibility with your existing system, as mismatched sizes can lead to leaks or inefficiencies.

Tips: Always check the manufacturer's specifications and user reviews to gauge performance and reliability. It's also beneficial to consult with a professional if you're unsure, as they can provide tailored recommendations based on your specific requirements. Lastly, don’t ignore maintenance considerations; choosing a valve that is easy to service can save time and costs in the long run.

When selecting the best gas safety valve for your specific applications, it's essential to understand the various environments in which these valves operate. Different applications, such as residential heating systems, industrial machinery, and commercial kitchens, have distinct requirements for gas safety valves. For instance, residential valves focus on efficiency and compliance with safety standards, often featuring straightforward designs. On the other hand, industrial applications may require robust valves that can withstand higher pressures and temperatures, as well as the capability to handle diverse gas types.

Additionally, the method of operation plays a crucial role in the choice of valve. There are automatic and manual safety valves; automatic valves are preferable in systems where constant monitoring is necessary, such as in commercial kitchens that utilize gas ranges. Manual valves, however, may be more suitable for low-risk environments where user intervention and oversight are feasible. Understanding these nuances can help ensure that you select a gas safety valve that not only meets safety regulations but also aligns with your specific operational needs.

Regular maintenance and inspection of gas safety valves are crucial to ensure their optimal performance and reliability. Gas safety valves should be inspected at scheduled intervals, typically every six months, to check for signs of wear, corrosion, or damage. During inspections, technicians should verify that the valve operates smoothly and seals properly, which is vital for preventing gas leaks. Any abnormal sounds or irregularities during operation may indicate a need for immediate repair or replacement.

In addition to regular inspections, proper maintenance practices can prolong the life of gas safety valves. This includes cleaning the valve components to remove dirt and debris that may cause operational issues. Lubrication of moving parts can also enhance performance, ensuring that the valve responds promptly to pressure changes. Operators must be trained to recognize the importance of these practices and should keep detailed records of all maintenance activities, including inspections and repairs. This proactive approach not only ensures safety but also complies with industry regulations and standards.

When choosing a gas safety valve, avoiding common mistakes is crucial to ensure both safety and efficiency. One prevalent error is overlooking the valve's pressure rating. According to a report from the American Society of Mechanical Engineers (ASME), improper pressure ratings can lead to catastrophic failures in gas systems, resulting in potential hazards. It's essential to select a valve that not only matches the system's operational pressure but also accounts for pressure fluctuations that may occur.

Another common mistake is neglecting the material compatibility. As noted in a study published by the International Journal of Industrial Safety, using valves made from incompatible materials can lead to corrosion and premature failure, especially in harsh environments. For instance, using a brass valve in a corrosive gas environment could significantly reduce its lifespan. Therefore, evaluating the chemical properties of gases and selecting valves made from materials suited for those conditions is critical to maintaining system integrity and safety.

Lastly, insufficient attention to the valve's certification and compliance with industry standards can also pose risks. Industry reports indicate that valves must meet specific safety standards, such as those set by the American National Standards Institute (ANSI), to ensure performance and reliability. Failing to verify these certifications could lead to equipment failures, regulatory fines, and severe safety repercussions.

© Shipham Valves 2025. All Rights Reserved.

Website By PS Website Design Ltd

Request a Quote/Further Information

Download

We use cookies on this website, by continuing to browse the site you are agreeing to our use of cookies. Find out more.